Nitrogen has a very important role on the earth for e.g., it is a major component of protein and nucleic acids. However, it is abundant in the atmosphere but cannot be used for humankind unless it is converted to some reactive form (such as ammonia) because N2 is chemically inert due to strong 𝑁 ≡ 𝑁 triple bond. Ammonia (NH3) has a wide application such as fertilizers, production of plastics, explosives, nitric acid, and the intermediates for dyes & pharmaceuticals. Currently, for the industries, the most widely adopted route for NH3 synthesis is the Haber-Bosch process and it is an energy intensive process. N2 molecule has a large dissociation energy ⁓941 kJ mol-1 and therefore requires harsh conditions such as high temperature (⁓400-600 ᵒC) and high pressure (100-200 atm). The reaction is given as below:

𝑁2 + 3𝐻2 → 2𝑁𝐻3 ∆𝐻 = −91.8 𝑘𝐽/𝑚𝑜l

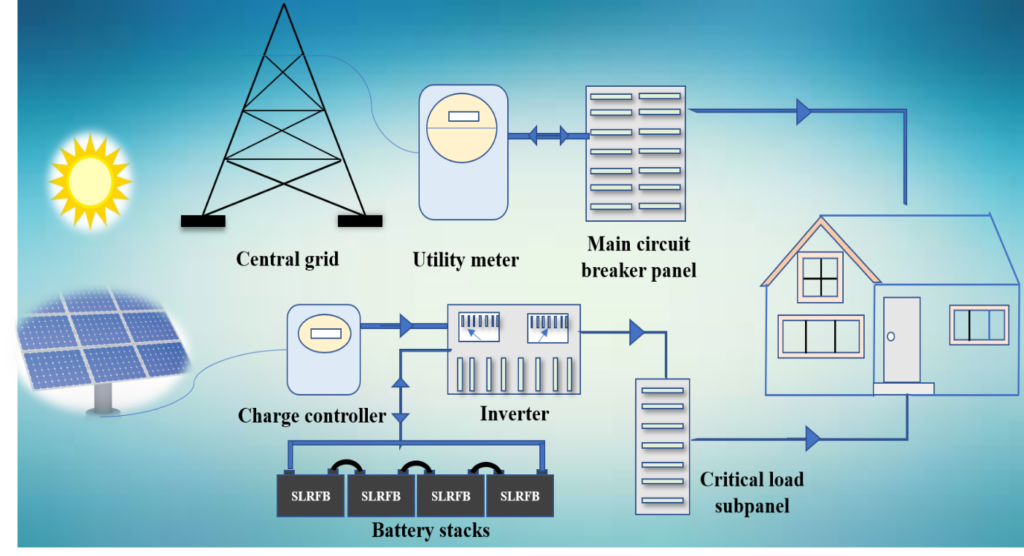

In 2020, the global NH3 production through Haber process was ⁓182 million metric tons. In Haber-Bosch process, NH3 is produced by reacting atmospheric N2 with H2 employing a metal catalyst under high temperature and pressure, in which H2 is generated through steam reforming of methane. Moreover, steam reforming of methane is an endothermic process and therefore requires high temperatures, consumes huge amount of energy (⁓1.5% of world’s total energy, and also causes 2% of total greenhouse gases. Therefore, an alternative approach for producing NH3 at ambient condition is highly recommendable. Electrochemical N2 reduction (NRR) has been suggested to be a sustainable approach to produce NH3 at ambient condition. In NRR, renewable energy generated from solar and wind can be used for NH3 synthesis, and no need of H2 gas production because N2 reacts with protons and electrons, generated via electrochemical water splitting. Therefore, electro-catalytic NRR happening at ambient condition could be an energy storage solution for storing excess energy produced at times by an intermittent renewable energy source. However, the yield of NRR process is very low due to less faradaic efficiency (FE) (defines as the efficiency with which charge is transferred in a system to facilitate an electrochemical reaction). The major cause of less FE is the side reaction happening during the process such as hydrogen evolution reaction (HER) which compete with the NRR (due to the similar free energy of both the reactions) whenever an aqueous electrolyte is used. Therefore, a suitable catalyst is required to facilitate the NRR with high efficiency. The desirable parameters for NRR electrocatalyst are (1) the selectivity of NRR over HER i.e., to shift the HER at high overpotential, (ii) increase the efficiency of overall NRR process, and (iii) improve the yield of NH3 production. Single metal atom or ions are an attractive solution for NRR catalyst, in particular gold (Au) atoms supported on nitrogen doped porous carbon (NDPC) has been proved to be an efficient catalyst for NRR and gives an FE of 12.3%. In Au supported NDPC, Au atoms are the active sites for the NRR, in which N2 molecules get adsorbed on the Au atoms and polarized due to positive charge of Au and negative charge of the nitrogen atoms of NDPC and therefore causes the 𝑁 ≡ 𝑁 bond activation at ambient condition. Lithium (Li) mediated NRR (Li-NRR) is also one of the reliable approaches for the NH3 synthesis in non-aqueous electrolytes. In Li-NRR, Li+ reduces to Li metal and metallic Li can spontaneously react with nitrogen to activate 𝑁 ≡ 𝑁 triple bond at ambient conditions to form a nitrogenous lithium compound and is subsequently converted to NH3 by proton sources. Beside Li-NRR, an electrocatalytic nitrate and nitrite (NOx – ) reduction reaction (NtrRR) has been also suggested as an efficient way to produce NH3. However, the major challenge of NtrRR is achieving an economical oxidation of N2 to nitrate, nitrite or NOx. Recently, at IIT Madras, Prof. R. Kothandaraman research group has been explored an electrocatalyst for NRR. The catalyst is based on tiara like nickel-thiolate cluster, [Ni6(PET)12] (where, PET = 2-phenylethanethiol) in non-aqueous electrolyte. By employing this electrocatalyst, they have produced NH3 with good faradaic efficiency of 25 ± 1.7 %. These findings suggests that atom-precise cluster material is a solution for green NH3 production using renewable energy.

Author: Dr. Nandini Jaiswal Institute Post-Doctoral Fellow, Clean Energy Lab, Prof. Kothandaraman Ramanujam Group Department of Chemistry, Indian Institute of Technology, Madras