India is the third largest energy-consuming country in the world. With the government making huge advancements to provide electrification (according to the Renewable Energy Report 2021 by IEA, 100 million people gained access to residential electricity in 2018 alone) for residential users, India has an enormous energy demand. To tackle this, the government has planned to increase renewable generating capacity from 175 GW in 2022 to 450 GW in 2030 (Based on the IEA report). As the world is pushing towards the use of clean and renewable sources of energy, India faces three major challenges: (1) providing affordable and reliable energy access to consumers; (2) safe and reliable integration of renewable energy shares, and (3) reduce emissions to accomplish the objectives for climate change. Due to the above challenges and the intermittent nature of power delivery from renewable sources, energy storage devices become critical in providing power reliability.

Energy storage of hundreds of kWh to MWh sizing is required for grid-scale storage from renewable energy sources during the peak generation period. Pumped hydroelectric energy storage, thermal energy storage, electrochemical energy storage, and mechanical storage systems are a few of the existing technologies for grid-scale storage applications. The recent advancements in electrochemical energy storage systems have helped us reduce the shortfall of better energy storage. Lithium-ion or lithium polymer-based battery is a technology revolutionizing the smart electronics industry and the automobile sector. Nevertheless, due to the limitations like cost and resource availability for the grid-scale, the potential of lithium-ion-based batteries is yet to be deployed at scale in India. Redox flow batteries (RFB) are one such technology that can be scaled for achieving the grid-scale storage application. RFB has a unique capability where the energy stored and power delivered can be controlled independently.

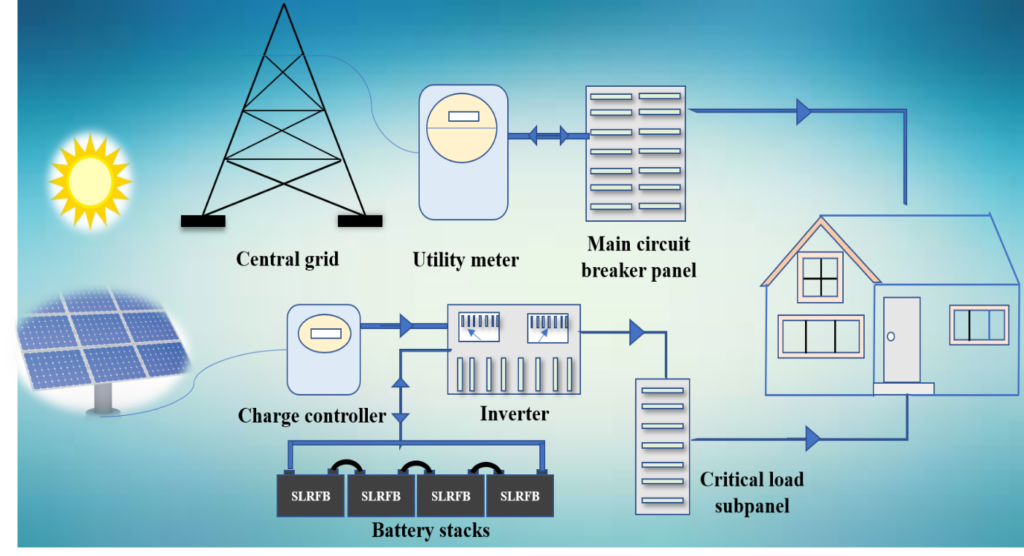

RFBs store electrical energy with the help of two different redox couples in external electrolytic tanks. The concentration and volume of electrolytes determine the energy storage capacity (kWh) of RFB. The storage capacity can be varied by simply changing the quantity and concentration of electrolytes. The power delivery, on the other hand, can be varied by adjusting the size of the battery. Few popular chemistries in RFBs are vanadium-vanadium, iron-vanadium, zinc-bromine, zinc-iron, and hydrogen-bromine. Vanadium redox flow batteries (VRFB), are the most popular among the different chemistries used in RFB. The general schematic for the RFB is given in Figure 1. The electrolytes are pumped to respective electrodes to convert chemical energy to electrical energy during the discharging process or vice versa during the charging process. The vanadium ion in different oxidation states in the electrolyte will either lose or gain electrons during the charging or discharging process. Figure 2 shows the charging and discharging process in a VRFB.

Figure 1. General Schematic of Redox Flow Battery

Figure 2. Charging and Discharging cycles in RFB

At the Energy and Emission Research Group (EnERG) IIT Madras, we work on parametric optimization of VRFBs to achieve maximum energy efficiency at different current densities. For this, we built a data model for energy efficiency predictions. The data model was first validated using literature and experiments to check for the deviations between predicted and actual values. The model was then used to determine the best parametric settings to achieve maximum energy efficiency (> 90). At present, we have achieved a maximum energy efficiency of 87 % in our (10 cm x 10 cm) VRFB prototype at a current density of 50 mA cm-2. We are now conducting further optimizations to improve the energy efficiency to > 90 % at the current density range of 50 – 200 mA cm-2.

Figure 3. Vanadium Redox Flow Battery developed in EnERG, IIT Madras

Author: Gautam Subburaj, Research Scholar, EnERG lab, IIT Madras