Carbon dioxide (CO2) is one of the principal greenhouse gas responsible for climate change. When fossil fuels are used to provide power and heat, significant volumes of CO2 are released into the atmosphere. Attempts to lower CO2 and other greenhouse gas emissions have been made in response to the growing CO2 concentration in the atmosphere. Since the onset of industrialization, CO2 emissions into the atmosphere have increased exponentially, leading to an increase in atmospheric CO2 concentration during the past 50 years. Due to the industrialization, the expansion of transportation, and the urbanization of cities, India is one of the major sources of CO2 emission. Power plants use fuel to produce electricity, and the burning of coal produces a significant amount of CO2 emission. If we don’t find a way to capture the CO2 gas or to convert it, the CO2 emission will rise and keep rising in the future.

Different sources for CO2 capture

The carbon-capturing process from various sources is classified into three categories such as post combustion, pre-combustion, and oxy-combustion.

Post-combustion

In this process, after the combustion of fuel in the presence of air, emitted CO2 will be captured from flue gas. This procedure is the one that is most frequently used in large-scale operations due to presence of fixed amount of CO2 for a particular source. The simplest and easiest technique to retrofit into thermal power plants and other sources is post-combustion.

Oxy-fuel CO2 combustion

In oxy-fuel CO2 combustion process, instead of air for the combustion of fuel oxygen is being used as the oxidant. Later from flue gas CO2 is separated. For small scale industry this method generally used.

Pre-combustion

In Pre-combustion process, the hydrocarbon present in the fuel will convert into synthetic gas such as carbon monoxide (CO) and hydrogen (H2) and then CO will convert into CO2 using water. Later H2 is separated from CO2.

Comparing all the processes, post-combustion is an easier and more conventional method used in power plants for the separation of CO2 from flue gases. The commercialization of these techniques involves overcoming several technological challenges related to the difficult process of CO2 capture. The expense of the CO2 capture process, which is a major impediment to its wide-scale commercialization, and the fact that the CO2 capture technology now in use relies on amine-solvents are also substantial roadblocks (monoethanolamine, MEA).

A chemical reaction with a high enthalpy of reaction is involved in this process. As a result, the regeneration step’s release of the collected CO2 requires a lot of heat. The currently used CO2 collecting techniques are inefficient and unsuitable for large-scale use. Therefore, a lot of research has driven the development of innovative CO2 capture techniques, materials, and designs, such as membranes, solid adsorbents, chemical/physical adsorption, and biomimetic systems. For effective CO2 absorption and subsequent regeneration for additional usage or sequestration, it is necessary to find more effective, low-cost alternatives.

One of the more viable options is CO2 absorption in liquid salts. The system simply employs specially formulated salts, commonly referred to as ionic liquids, that are liquid at room temperature to absorb the carbon dioxide. Metal-Organic Frameworks (MOFs) and ionic liquids (ILs) were offered as alternatives to commercial volatile solvents as new and developing materials for CO2 capture. The application interest of ionic liquids as a CO2 capture is given significant attention. As a result, the focus will be on recent advances in creating appropriate ionic liquids for CO2 extraction from flue-gas streams and other point sources.

Ionic Liquids (ILs) and CO2 Capture

Salts made up of ions, ionic liquids (IL) are defined as having a melting point of less than 100 ˚C. Before Freemantle wrote an essay in 1998 addressing the possible use of ionic liquids as solvents for green chemistry, the uses of ionic liquids were extremely restricted. Amazing characteristics of ILs are their great thermal stability, low vapour pressure, non-flammability, tunability, solvation properties, and high CO2 solubility. Researchers were motivated to switch from the old industrial solvents known as volatile organic compounds (VOCs) to ionic liquids by these special features. The traditional volatile solvents were replaced with non-volatile ionic liquids to reduce environmental contamination. The method used in the present invention is energy efficient compared to other methods; it offers the following features and benefits: 1) The Lewis acid-base interaction between the ionic liquids and the CO2 considerably enhanced the ionic liquid trapping quantity of CO2, up to 3 moles per mole of ionic liquid, by developing different spatial arrangements and tuning structure of cation and anions. 2) Synthesis procedure is quite easy and by synthesis we can minimize the production cost of ILs. 3) We can separate the ILs and CO2 from their mixture so that we can reuse the ILs for the subsequent CO2 capture batch process. By simply heating we can separate CO2 from the IL + CO2 combination, this regeneration process may be repeated five to six times.

Amine based IL -CO2 capture process

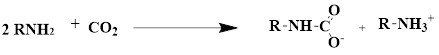

ILs’ amine groups associated with their cations or anions often react with CO2 in a variety of ways. Similar to an aqueous amine system, a single or double functionalized amine combines with CO2 to produce the desired product.

Nonamine -based IL-CO2 chemical interaction

The fundamental drawback of amine-based ILs is that we can’t reuse them for other applications because to their excessive viscosity. Furthermore, CO2 regeneration is highly challenging due of the significant interaction between CO2 and ILs for ILs based on amines. Phenolic ILs play a significant part in the effective and reversible capture of CO2 among all non-amine based ILs. Phenol acts as an anion in phenolic ILs, and its physicochemical properties and CO2 absorption capability rely on its capacity for electron donation, electron withdrawal, and substituent positioning.

The current article compares the use of ionic liquids to commercially available conventional reagents for the effective separation of CO2 from diverse sources employing absorption, adsorption, technologies. Ionic liquids unique and designing ability and possibilities for CO2 capture were demonstrated. Due to the higher bonding affinity between IL and CO2, the addition of ionic liquids to the absorption and adsorption methods significantly improves the CO2 capture. In accordance with the structure and functional groups connected to the cation or anion, ionic liquids functioned as both physical and chemical absorbents.

Author – Indrajit Das, Research Scholar, and Prof Ramesh L. Gardas, both with Department of Chemistry, Indian Institute of Technology, Madras.